Manufacturers that run injection molding, extrusion, or recycling lines face the same recurring problem: getting the right material, at the right ratio, into the machine — reliably, repeatedly, and with audit-ready proof. Traditional central feeding systems and newer automatic feeding solutions both move material; but when precision, traceability and fast changeovers matter, an automatic weighing & metering system becomes the control layer that turns bulk handling into consistent production output.

The uploaded technical note describes two distinct approaches:

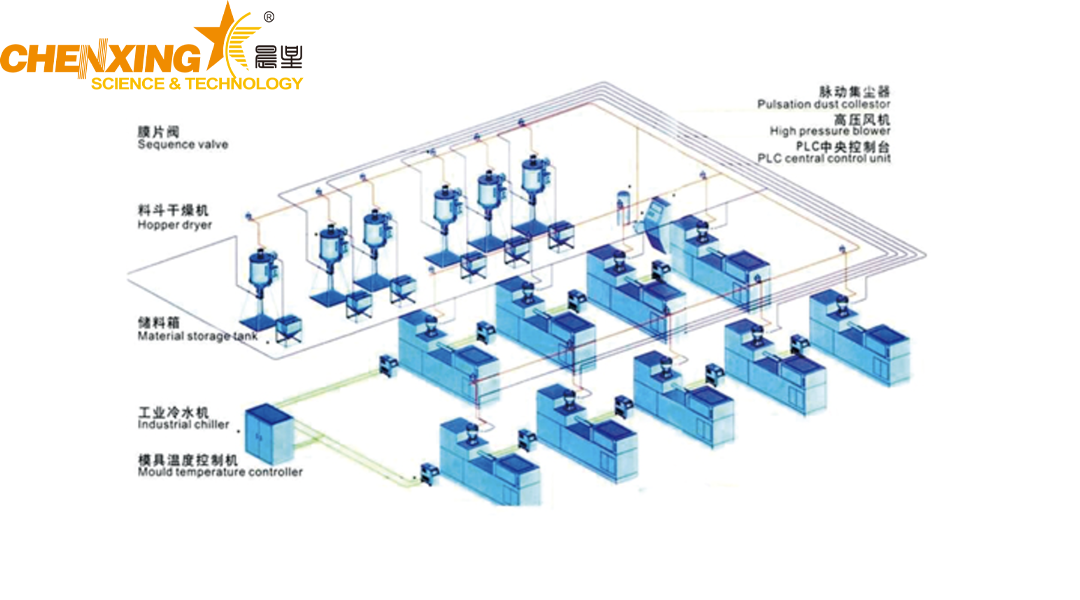

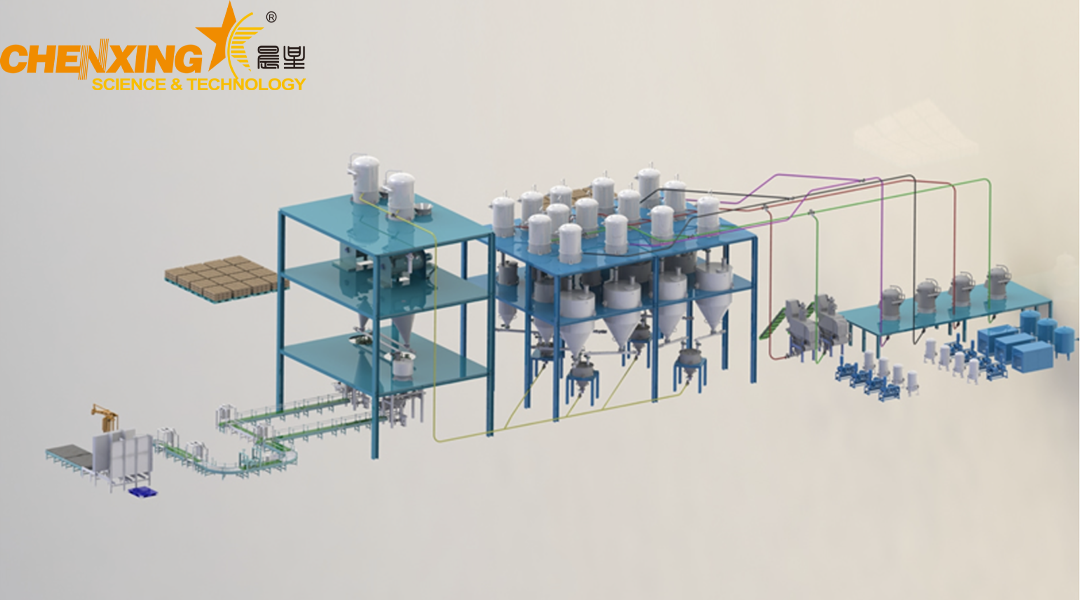

Central feeding (central material distribution) uses vacuum transport to pull resin from storage silos to a centralized dehumidifying/drying station, then distributes dried material to individual machines through a pipe network. This design emphasizes continuous drying, pipe cleaning cycles and dust filtration to keep material dry and consistent.

Automatic feeding works by cycling a pneumatic feed (using short bursts of vacuum/air flow), often with a single motor serving multiple lines through directional valves. Material is transported in pulses to local hoppers and dosing points; control logic coordinates which line receives material and when, enabling flexible, energy-efficient operation.

Both models aim to prevent re-moistening, avoid blockages and remove dust — but they differ in topology and the level of local control. The central system centralizes drying and filtration; automatic feeding decentralizes the transport pulses while still leveraging central drying when required.

Moving material is one thing. Measuring it accurately and controlling the flow are another. Automatic weighing & metering systems fill that gap and bring four immediate benefits:

Gravimetric accuracy (batch and continuous): Built-in load cells or weigh hoppers measure material mass in real time so batches hit recipe targets without guesswork.

Traceability & audit trails: Each batch can store time-stamped weight, lot number, operator and material source — crucial for quality control and compliance.

3.Repeatable changeovers: Recipe-driven dosing reduces manual adjustments when switching grades, colors or part families — shortening downtime and lowering scrap.

4.Material savings: Precise metering reduces giveaway (overdose) and rework, improving margin on commodity resins.

In other words: feeding provides the supply; weighing & metering ensures the right amount reaches the machine at the right time.

A modern system designed for integration into central or automatic feeding architectures should include these functions:

Weigh hoppers with load-cell feedback: Fast, accurate mass measurement for both batch dosing and continuous loss-in-weight control (without specifying model parameters).

Recipe management and version control: Save formulae (ratios, tolerances) and enforce role-based approvals to guarantee process discipline.

Proportioning and blending logic: Combine virgin resin, regrind and additives in precise ratios, with multi-stage coarse/fine dosing control.

Auto-tare and self-calibration: Reduce operator intervention and ensure stability after long idle times or line changeover.

Dust-tolerant, IP-rated components: Sealed load-cell enclosures and filtered vents for dusty or humid environments.

PLC/SCADA / MES connectivity: Push batch data to ERP or quality systems and accept upstream commands (start/stop/changeover).

Alarms & interlocks: Automatic rejection, hold or purge when weights deviate from tolerances or when hopper bridging occurs.

Together these capabilities convert material handling into a predictable, auditable manufacturing input.

The uploaded document emphasizes the role of central drying (dehumidifying) and vacuum transport in maintaining material quality during transfer. An automatic weighing & metering system integrates with that infrastructure in three useful ways:

Upstream drying consistency: Weighing systems expect consistent feed density and moisture. Pairing with central dehumidifying ensures the material arriving to the weigh hopper behaves predictably.

Pulsed transport compatibility: Automatic feeding often uses valves and motor cycles to share a single vacuum pump among lines. Weighing software can coordinate with valve states to prevent over-filling during transport pulses and to confirm material arrival before dosing.

Auto-clean cycles and pipe purge verification: Central systems that perform pipeline cleaning between transfers benefit from weight confirmation — the weigh system records "no fill" events and enforces purge sequences, reducing cross-contamination risks.

In short: central drying keeps material dry; automatic feeding moves it flexibly; weighing & metering makes sure the right mass is delivered and logged.

Faster, lower-risk changeovers. When a line must switch from a pelletized resin to a dusty regrind or a colored compound, operators rely on recipe recall and the weigh system’s auto-tare to avoid manual recalculations. That reduces trial-and-error runs and scrap.

Less manual inventory loss. Accurate metering avoids chronic overfeeding, cutting resin giveaway that quietly erodes margins.

Better quality records for audits. Batch-by-batch weight logs simplify root-cause work and customer traceability.

Cleaner operation with fewer clogs. Integrated interlocks (weigh ↔ feed ↔ purge) reduce the need for emergency line cleaning and the downtime that follows.

These outcomes are repeatedly reported by processors that move from manual or volumetric feeding to closed-loop gravimetric control.

Use this short checklist when specifying a system:

Material profile: Will you handle pellets, powders, flakes, or blends? Ask how the vendor handles bridging, segregation and hygroscopic feedstocks.

Batch vs. continuous need: Do you require intermittent batch dosing, continuous loss-in-weight control, or both.

Recipe & access control: Ensure the system supports locked recipe libraries and permissioned edits.

Integration requirements: Confirm native connectivity to your PLC/MES/WMS and AGV or central vacuum control.

Environmental tolerance: Look for IP-rated enclosures and sealed load cells if dust or humidity is present.

Service & calibration: Verify on-site calibration schedules, remote diagnostic options, and spare parts availability.

Experience: Proven projects show that pairing central drying with automatic feeding and gravimetric metering reduces out-of-spec parts and material waste (the technical differences between central and automatic feeding are summarized in the attached document)

Expertise: Automated weighing requires application know-how — correct scale geometry, vibration filtration, and software tuning — to be accurate on dusty or pulsing lines. That expertise is what separates simple scales from production-grade metering systems.

Authoritativeness: Look for suppliers who publish technical usage guides, run material trials, and provide FAT/SAT protocols that align with your plant’s SOPs.

Trustworthiness: Request audit logs, test certificates for load cells, and a clear service contract — these are the documents that protect you when uptime or product compliance matters.

Q: Can automatic weighing be retrofitted to my existing central feeding or automatic feeding network?

A: Yes. Most systems are modular: you can add weigh hoppers, load cells and local control cabinets that communicate with existing PLCs. The tricky part is mechanical: get a vendor to model the hopper geometry and to perform material trials.

Q: Do weighing systems handle both powders and pellets?

A: Modern systems include anti-bridging designs and multi-mode feeding logic, but you should validate with a sample test — powders require different feed control strategies than pellets.

Q: How is accuracy maintained when an AGV docks and the docking motion causes vibration?

A: Production-grade weigh systems employ vibration filtering, stabilization delays, or docking clamps that isolate the scale during measurement.

Q: What documentation should I insist on?

A: FAT/SAT protocols, calibration reports for load cells, software validation, and a clear maintenance schedule.

Material audit: Provide vendor with representative samples and duty cycles.

Pilot trial: Run a small-scale line or a full FAT with your materials to confirm accuracy and anti-bridging logic.

Integration run: Test PLC/MES messaging, recipe downloads, and AGV docking scenarios.

Operator training & SOPs: Train teams on exception handling (bridging, under/overweight) and maintenance.

Tune & ramp: Start with conservative tolerances, monitor performance and tighten setpoints as stability proves out.

If you’re evaluating upgrades or planning a new modular unloading/feeding project, consider a material trial: send a sample, and ask the supplier to run it on a demo weigh hopper under representative pulsed-vacuum conditions. The proof is in the data — repeatable weight traces and clean batch reports mean predictable production.

Learn more about automatic weighing & metering and request a live demonstration at: www.chenxingmachinery.com — our engineering team can run material trials, supply FAT documentation and help design the weighing layer that turns your modular feeding into a production-grade system.

Introduction: Why New Composite Building Materials Matter TodayPlastic waste is one of the defining environmental challenges of our era — yet it is also a feedstock with enormous untapped value. Advances in recycling technology now let plants convert post-consumer and post-industrial plastics into r

Understanding the Importance of a Formula Mixing SystemIn modern plastics manufacturing and chemical processing, accuracy and consistency define success. Whether you’re producing PVC compounds, masterbatch, or polymer blends, the automatic formula mixing machine—also known as a solid material dosing

Introduction — the shift toward smarter feeding and dosingManufacturers that run injection molding, extrusion, or recycling lines face the same recurring problem: getting the right material, at the right ratio, into the machine — reliably, repeatedly, and with audit-ready proof. Traditional central

Upgrade modular unloading with automatic weighing & metering. Faster changeovers, AGV integration, sealed dust control, and audit-ready batch records.

Learn whether PP electrical conduit and PE drainage pipes can be manufactured on one extrusion line. Understand material differences, production requirements, and the right solution for your plastic pipe production.

Discover why the same SHR series high-speed mixer model may have different spindle speeds. Learn the 6 key factors and get expert tips for your plastic mixing process.

Upgrade your extrusion line with a 16-zone single screw extruder control system for higher precision, stability, and production efficiency.

Learn why high speed mixers for plastic are crucial in today’s manufacturing. Discover SHR series, SRL-Z, and SRL-W mixers, and how they enhance productivity and product quality.

High-speed mixers are widely used across various industries, including plastics, rubber, dyes, food, and household chemicals, for mixing, blending, drying, and coloring materials. With their versatile applications, high-speed mixers have become indispensable in modern manufacturing processes.Feature

Learn how plastic extrusion works, from single and twin screw extruders to full extrusion line setups. Discover process steps, materials, and real-world applications.